Gravimetric Blending

In 2016, Maguire celebrated 50,000 installations of Maguire Weigh Scale Blender worldwide. Maguire manufacturers up to 100 different models which are available to blend up to twelve components at rates up to 8,000 lbs/hr – 3,600 kg/hr. Maguire products provide the most cost-effective Weigh Scale blenders available with most leading plants in Australia & New Zealand now becoming standardised on Maguire blenders due to their remarkable reliability and advanced features.

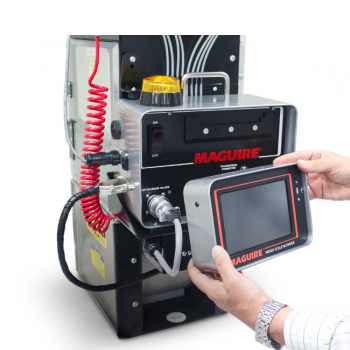

A weigh scale blender for injection moulders and small extruders. Ideal for processors with frequent material change.

For injection & blow moulders, extrusion lines. Ideal for processors with frequent material changes.

Weigh scale blender for large high output extrusion lines, blown film lines, large central blending systems and multiple component plastic recycling applications.

Specialist dosing design for a combination of pellets, powders, flakes liquids or other challenging materials that need precise control.

Weigh scale blenders for high output extrusion lines and multiple component plastic recycling applications.

Dosing designed for low density and poor flow materials like regrind, flake, wood flour, with a wide choice of add on feeders for specialist dosing applications.

Dosing designed for low density and poor flow materials like regrind, flake, wood flour, with a wide choice of add on feeders for specialist dosing applications.