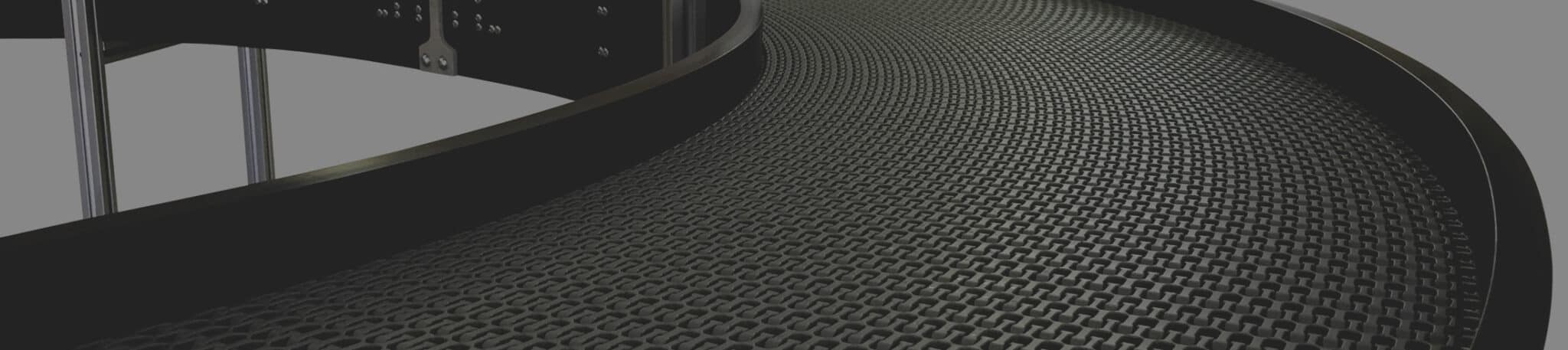

Conveyor Accessories

Optimising Material Handling with Conveyor Accessories

Fleming offers a comprehensive range of conveyor accessories designed to optimise material handling efficiency and enhance product quality. Among these accessories are DynaCon Cooling Conveyors, which provide cost-effective solutions for rapidly cooling hot parts or products on standard conveyor systems. Internal and overhead cooling fans ensure efficient cooling across conveyor sections, while portable chiller air units offer spot cooling where needed, saving time and manpower in production processes.

Efficient Water Bath Conveyors

For applications requiring water immersion, DynaCon Water Bath Conveyors excel in providing uniform part cooling. These modular conveyors are constructed with corrosion-resistant plastic belts that require no lubrication, making them ideal for complete water submersion and washdown applications without the need for expensive custom conveyors. This versatility ensures efficient and hygienic handling of parts in various manufacturing environments.

Specialised Conveyor Accessories

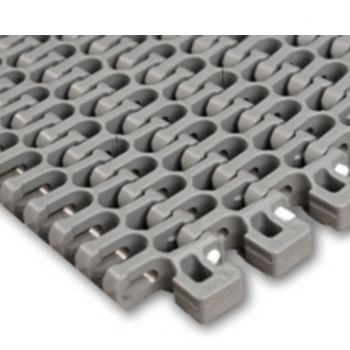

Fleming also stocks accessories like DynaCon Internal Metal Detectors, integrated directly into conveyor modules for reliable metal detection across various temperatures and metal types. Additionally, the DynaCon Tunnel Filter keeps parts clean during conveying by removing airborne particles, ensuring product integrity. DynaCon Belting, featuring self-lubricating plastic link-style belts, offers durability and ease of maintenance for diverse conveyor applications, including modular and specialty conveyors.

These conveyor accessories from Fleming empower businesses to optimise conveyor systems for specific needs, whether it’s cooling, metal detection, particle filtration, or product protection. The innovative design and durability of these accessories contribute to increased productivity, reduced maintenance costs, and improved operational safety in material handling processes.

Dynamic Conveyor offers three options that save time, money and manpower by quickly cooling hot parts or product on any new or existing standard conveyor.

DynaCon Modular Conveyors offer the option to be submerged in water for uniform cooling of parts as they are transferred to another conveyor or work station.

These plastic Belt Conveyors never require lubrication and are corrosion and rust-resistant, making them ideal for complete water immersion and wash down applications without requiring expensive custom conveyors.

The user-friendly controls enable sensor operation in extreme temperatures.

The Metal Detector is capable of detecting all metals – steel, aluminum, copper, brass and stainless steel. The metal detector is integrated into the conveyor module and is available in widths ranging from 8” to 36”. Metal detector modules can be integrated into new or existing conveyors.

DynaCon Tunnel Filter

Keeps parts clean during the conveying process.

The Dynacon Tunnel Filter removes at least 99.97% of the airborne particles 0.3 micrometers in diameter (larger or smaller particles are filtered at higher efficiency)

DynaCon Covers

Use for safety, dust protection, part protection or cooling applications.

Clear covers can be mounted to any section of the conveyor for safety, dust protection, part protection, or cooling applications, offering versatile functionality to enhance operational safety and product integrity.

Link style belting is utilised with DynaCon Modular Conveyors and Hybrid Speciality Conveyors. Available in varying types for all applications