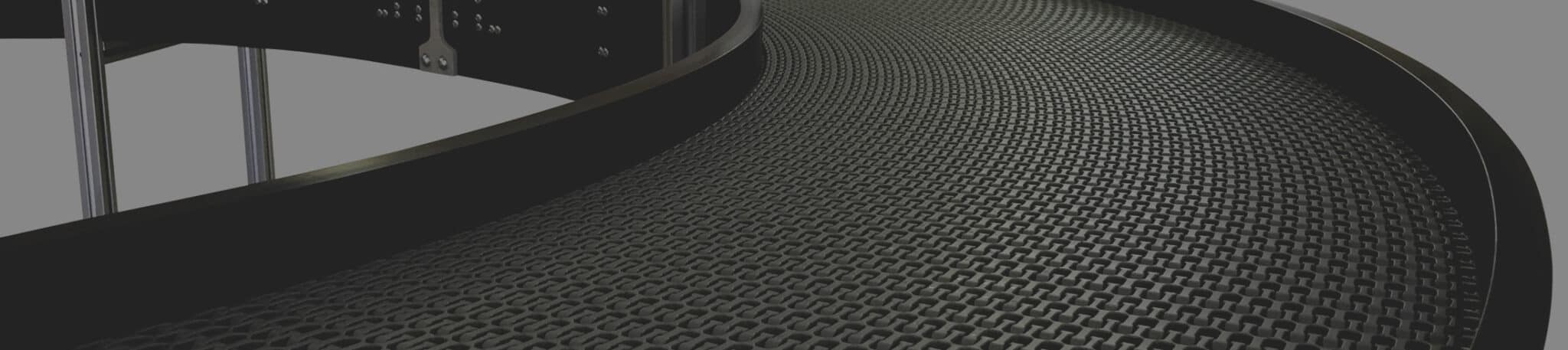

DynaCon Cooling Conveyors

Efficient Design and Cooling Capacity

The DynaCon Cooling Tunnel Conveyor is efficiently designed with standard-sized acrylic covers that snugly fit both top and bottom of standard DynaCon conveyor modules. It distributes air evenly through a 38% open flush grid belt and can handle up to 18,000 BTU/hr of cooled air when connected to an in-house forced air cooling source. This makes it suitable for a wide range of applications and allows parts to be cooled efficiently without the need for water baths.

Versatile Low Profile Design

The system’s low profile design, with standard covers mounting on bosses along the conveyor edge, facilitates air-cooling for low-profile parts. Moreover, by incorporating standard retaining flanges, the tunnel can easily accommodate larger parts, enhancing its versatility for various applications.

Flexible Cooling Solutions

The DynaCon Modular Conveyor System offers flexible cooling solutions such as internal cooling fans for cooling any section of the conveyor or the entire length, overhead cooling fans for cooling small to large parts, and a portable spot air cooling unit with chiller air for rapid part cooling. These features enhance the system’s adaptability and effectiveness in cooling parts across different scenarios and industries.