DynaCon Water Bath Conveyors

Efficient Water Cooling System

DynaCon conveyors are equipped with water-style belts and drive flights, which can be customised for optimal water cooling, ensuring rapid product cooling and expediting manufacturing processes. These conveyors, in combination with waterbath tanks, offer a streamlined solution for cooling parts efficiently. Tanks, constructed from robust 12-gauge stainless steel, can be enhanced with optional accessories like drip pans, overhead spray nozzles, casters, and cooling coils to minimize cooling time. They are designed to seamlessly integrate with DynaCon Plastic Belt Conveyors of varying widths and lengths, providing versatility and effectiveness in cooling operations.

Submersion Cooling for Uniform Results

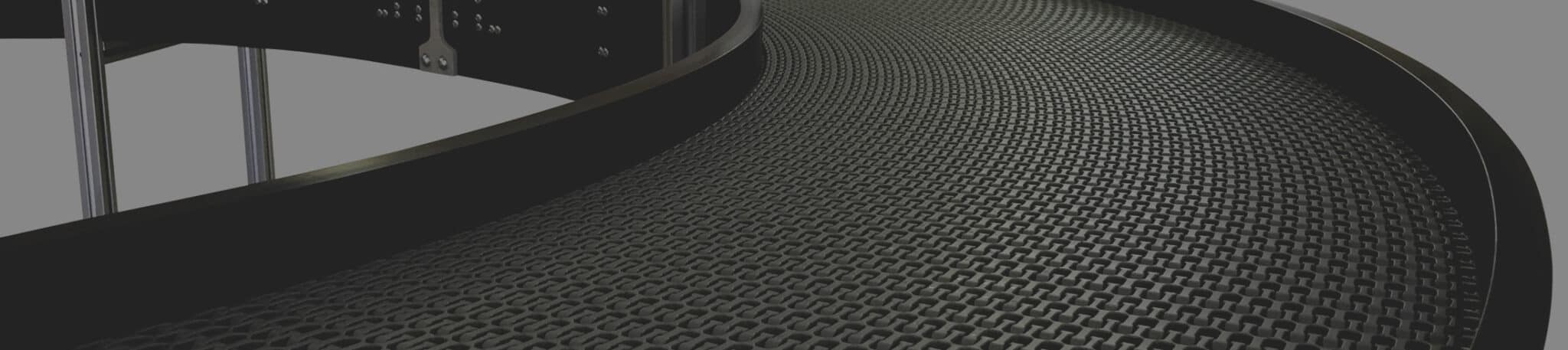

DynaCon Modular Conveyors present the option of submerging parts in water for uniform cooling as they transition between conveyors or workstations. The corrosion and rust-resistant Plastic Belt Conveyors, requiring no lubrication, are ideally suited for complete water immersion and washdown applications, eliminating the need for costly custom conveyors. In this setup, the feed end of the conveyor is submerged in a water tank, where parts undergo cooling before being transported out via an externally-powered incline. Various plastic link options are available to cater to diverse cooling requirements and conveyor configurations.

Key Benefits and Versatility

The DynaCon conveyors offer several key benefits, including uniform part cooling, corrosion resistance, and a variety of link style belting options. Constructed from durable 12-gauge stainless steel, the cooling tanks can be accessorised with optional features and are designed to accommodate DynaCon conveyors of different widths and lengths. This adaptability ensures efficient cooling operations across various industries and applications, making DynaCon conveyors a reliable choice for rapid product cooling with water.