Sorting Systems

Alternative system configurations for a wide range of applications.

Sesotec recycling sorting systems with chute are suitable for removing contaminants or impurities from material that has already been shredded. They sort plastic flakes and regrind as well as glass fragments. Sesotec offers machinery designed specifically for one purpose as well as universal multi-sensor systems for various sorting jobs.

Especially for the sorting of plastic flakes such as PET, HDPE or mixed plastics flakes Sesotec provides its FLAKE PURIFIER+ sorting systems.

Based on a modular concept these systems allow the combination of all available sensors for contaminant detection: Sensors for metal separation, sensors for colour separation / sorting, and sensors for the separation and sorting by plastic types. The information provided by the individual sensors is processed by the evaluation unit based on octa-core technology. Separation of material by air-blast unit.

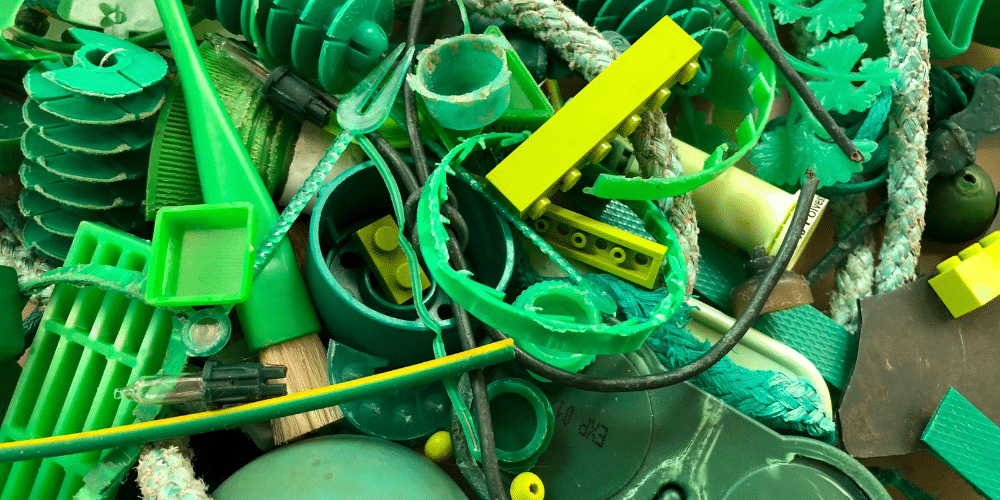

Universal application in plastics, metal, and electronic waste recycling

The multi-sensor sorting system is developed especially for sorting of three-dimensional material as well as for electronic waste. Varisort combines a vibratory feeder with a high-speed conveyor; eliminating the influences of weight, shape and abrasive characteristics of the material for improved sortation quality. As a result, previously impossible to sort material can now be processed.