14 Nov Enhance Efficiency and Flexibility with Fleming Dynamics’ Modular Conveyors

In today’s dynamic and modern world of manufacturing and logistics, the need for efficient and adaptable material handling solutions is paramount. Modular conveyor systems represent a significant advancement in material handling technology, offering a versatile, efficient, and cost-effective solution for a variety of industries. Their ability to adapt to changing operational needs, combined with ease of maintenance and scalability, makes them an invaluable asset in today’s fast-paced industrial landscape. As businesses continue to seek ways to optimise their processes and stay competitive, the adoption of modular conveyor systems is set to rise, driving greater efficiency and productivity across sectors.

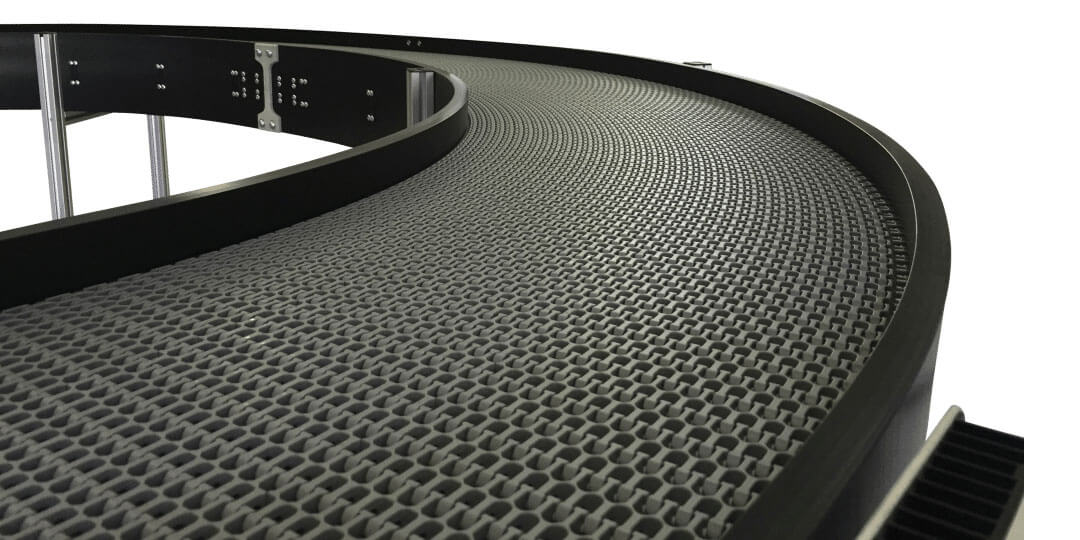

At Fleming Dynamics, our modular conveyors are a revolutionary approach when it comes to conveying, one that offers unparalleled flexibility, efficiency, and ease of maintenance, making our conveyors an essential component in modern industrial operations. What makes our conveyor systems one of the most preferred brands with our clients, is the provision of standardised, interchangeable modules, that can be easily assembled, disassembled, and reconfigured as per your requirements. Our modular conveyors typically include straight sections, curves, inclines, and declines, allowing for a customised layout that meets the specific needs of an operation. The modular designs of these conveyor systems make them highly versatile and adaptable to various applications and industries.

Key Features of Our Modular Conveyor Systems

1. Interchangeability: The standardised modules in our conveyor systems can be swapped out or added without significant downtime, providing a highly adaptable system.

2. Scalability: Our modern-day conveyor systems are designed to help you scale your business. New businesses can start with a basic system and expand it as their needs grow, ensuring a cost-effective solution.

3. Ease of Maintenance: The modular design of our conveyor systems allows for quick replacement of individual sections or components, reducing maintenance time and costs.

4. Customisable: Fleming Dynamics’ modular conveyors can be tailored to specific requirements, including different lengths, widths, and configurations, to optimise workflow and space utilisation.

5. Durability: Made from high-quality materials such as stainless steel, aluminum, and durable plastics, Our modular conveyors are built to withstand heavy-duty operations.

Benefits of Fleming’s Modular Conveyor Systems

1. Enhanced Flexibility: The ability to reconfigure our conveyor systems quickly means businesses can adapt to changes in production processes or layouts with minimal disruption.

2. Increased Efficiency: By optimising our modular conveyor layout, businesses can streamline their operations, reduce manual handling, and increase output.

3. Reduced Downtime: The ease of maintenance and quick replacement of parts of our conveyor systems minimise operational interruptions, ensuring continuous productivity.

4. Cost-Effectiveness: Modular conveyor systems provided by Fleming Dynamics offer a lower initial investment and reduced long-term costs due to their scalability and ease of maintenance.

5. Space Optimisation: Our conveyor systems offer customisable layouts that help you in maximising the use of available manufacturing space, which is crucial in industries with limited floor space.

Applications of Fleming Dynamics’ Modular Conveyor Systems

Our modular conveyors are utilised across a wide range of industries, each benefiting from their unique advantages:

1. Manufacturing: Used in assembly lines, packaging, and distribution, our modular conveyors enhance production efficiency and flexibility.

2. Food and Beverage: Designed to meet stringent hygiene standards, our conveyor systems facilitate the safe and efficient handling of food products.

3. Pharmaceuticals: Provide a clean and controlled environment for the transportation of sensitive products.

4. Automotive: Assistance offered by our conveyor systems in the movement of heavy components and assemblies improve the workflow and safety.

5. E-commerce and Retail: Our modular conveyors streamline order fulfillment processes, ensuring quick and accurate delivery of products.

About Fleming Dynamics Australia

Since 1981, Fleming Dynamics has been a trusted provider of industrial water chillers, modular conveyors, and recycling systems for Australian and New Zealand manufacturing industries. Known for expert engineering, reliable service, and sustainable solutions, Fleming Dynamics partners with top brands to deliver innovative, energy-efficient equipment. Our customer-first approach ensures responsive support and tailored solutions across a wide range of applications.

For more information, visit fleming.net.au.

No Comments