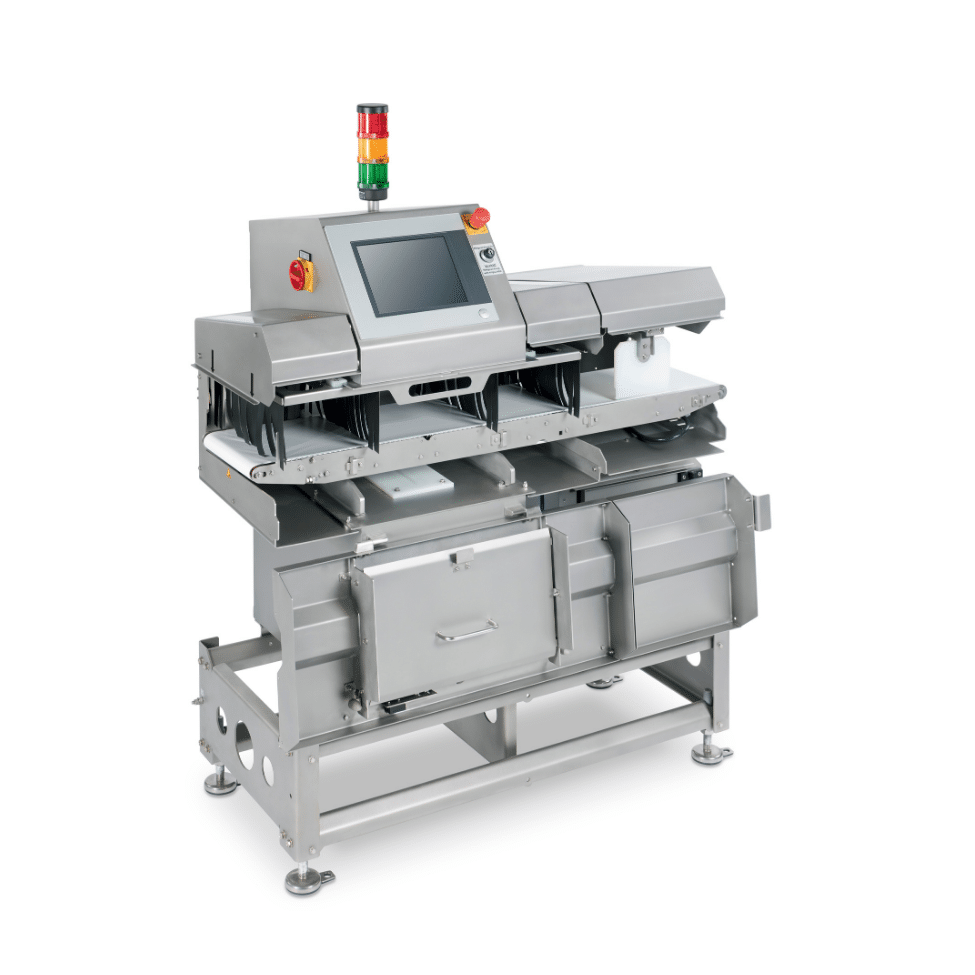

Sesotec Raycon EX1

RAYCON EX1 offers an affordable and effective solution for inspecting packaged products at the end of the production line. Emphasising a hygienic industrial design and user-friendly features, it stands out with its superior cleanability, maintainability, and easy handling.

Precision in Design and Operation

The RAYCON EX1 inspection system integrates crucial components, including an X-ray tube, transport system, detector unit, and an industry-type PC for image evaluation and rejection control. It excels in detecting contaminants based on density, chemical composition, or mechanical dimensions, covering metals, glass, ceramics, stones, and certain plastics. With an inspection area of 220/120 (W x H), throughput of approximately 220 pcs./min., and a detection capability starting from Ø 0.6 mm, it ensures efficient and accurate inspection.

Advanced Software and Hygienic Design

Equipped with high-performance industrial PC and visualisation software, the RAYCON EX1 boasts a 10″ LCD touch screen monitor, providing a user-friendly interface. Its advanced software features include Drag & Drop menus, autolearning with minimal samples, and automatic sensitivity adjustment, ensuring fast and hassle-free product setup. The system’s design prioritises hygiene and ease of maintenance, featuring inclined surfaces for easy water runoff, tool-less accessibility, and quick removal of curtains and conveyor belts.