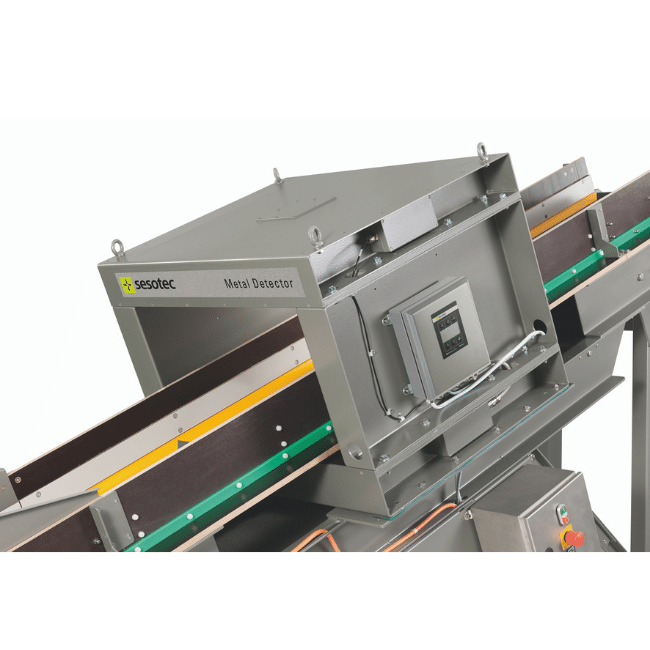

The C-SCAN DLS is a splitable metal detector designed for conveyor belts and material chutes. It excels in detecting both magnetic and non-magnetic metal contamination, even when enclosed in the product. This metal detector aims to reduce machinery failure, minimise production downtime, and ensure product quality, thereby preventing customer complaints. With a remarkably short break-even period, the C-SCAN DLS is suitable for analysing smalls and bulk materials with a material height over 100 mm. It boasts high scanning sensitivity to all metals, easy installation without belt disconnection, and a robust design for noise immunity.

Functional Highlights

The splitable tunnel detector DLS is employed for analysing materials on conveyor belts or chutes, especially in high-material scenarios. It detects magnetic and non-magnetic metal contaminations, such as steel, stainless steel, and aluminum, even when enclosed in the product. Upon metal detection, it triggers a signal device and separation system or sends a signal for process control. Typical application areas cover plastics, recycling, timber, chemical, textile, mining, and cement industries. The C-SCAN DLS provides machinery protection for various equipment like granulators, shredders, hocks, crushers, calenders, bandsaws, and planing machines.

Features and Scope

The C-SCAN DLS package includes the tunnel detector and the PRIMUS+ Control Unit. Additional features comprise adjustable metal impulse and delay times, a product memory for ten presets, and password protection for enhanced security. The system is characterized by its adaptability, user-friendly features, and resistance to external factors like electromagnetic pollution and vibrations, contributing to its overall effectiveness in enhancing operational efficiency.