Sesotec Protector

Exceptional Metal Contaminant Detection and Separation

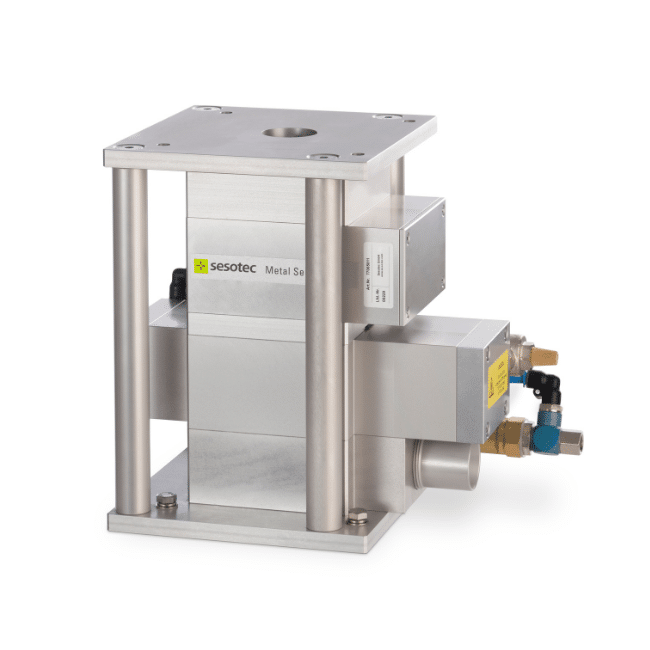

The PROTECTOR PROFESSIONAL, a high-performance metal separator designed for extruders, injection-molding, and blow-molding machines, excels in detecting and separating both magnetic and non-magnetic metal contaminants, even when enclosed in the product. This advanced system ensures reliable removal of contaminants from the material flow, significantly reducing costs associated with mold and machine damage, as well as production losses.

Precision in High Mechanical Loads

Equipped with extremely high scanning sensitivity, the PROTECTOR PROFESSIONAL maintains its efficiency even under substantial mechanical loads, such as heavy conveyors, dosing, mixing, and feeding units mounted on top. The space-saving and compact design facilitates quick and easy installation, with optional adapter plates available for various material conveyor connections. The system’s auto-set function, preset operating parameters, and the proven “Quick-Valve” reject unit contribute to minimal loss of good material, ensuring a rapid return on investment

Versatile Applications with Reliable Functionality

Installed directly above the material inlet of plastic processing machines, the PROTECTOR PROFESSIONAL guarantees a safe and reproducible function, even with materials containing a high regrind content. Its unique design, featuring an integrated reinforcing frame, ensures the highest scanning sensitivity for detecting the smallest metal particles, making it an ideal solution for machinery protection under high mechanical loads. The scope of delivery includes a metal separator with a detached Control Unit PRIMUS+, and optional accessories provide customization for specific needs, making it a valuable asset in the plastics-processing industry and beyond.